Warehouse Robots

Warehouse robots are an essential part of modern logistics strategy. A warehouse robot is designed to integrate into companies’ warehouse and logistics systems, whether it’s manufacturing companies, distribution centers, or retail stores. By implementing warehouse robots, your company can reap several benefits:

- Increased efficiency

- Precision and flexibility in handling goods

- Minimized resource waste and streamlined workflows

Zolvo A/S is an integrator of facility systems and solutions within companies’ internal logistics. We create innovative and sustainable solutions that help companies meet demand and ensure quick delivery.

We offer free consultation and assistance to clarify your company’s potential. Here we map out the possibilities for optimizing your warehouse processes and internal logistics.

Benefits of Warehouse Robots

Implementing warehouse robots brings significant benefits that can revolutionize the way your company handles its warehouse operations. Here are some of the benefits you can achieve:

Better Work Environment

Warehouse robots can handle the heaviest and most repetitive tasks, minimizing employees’ direct exposure to potentially harmful activities.

Increased Productivity

Warehouse robots work at a speed and precision that surpasses human capacity, meaning tasks like picking, packing, and sorting are performed faster and with fewer errors.

Space Optimization

Advanced systems with warehouse robots can store and retrieve items from densely packed storage spaces, ensuring optimal use of your warehouse capacity.

24/7 Operation

The ability of warehouse robots to work around the clock allows companies to maximize their operations 24/7 without the additional costs and logistical challenges associated with shift work.

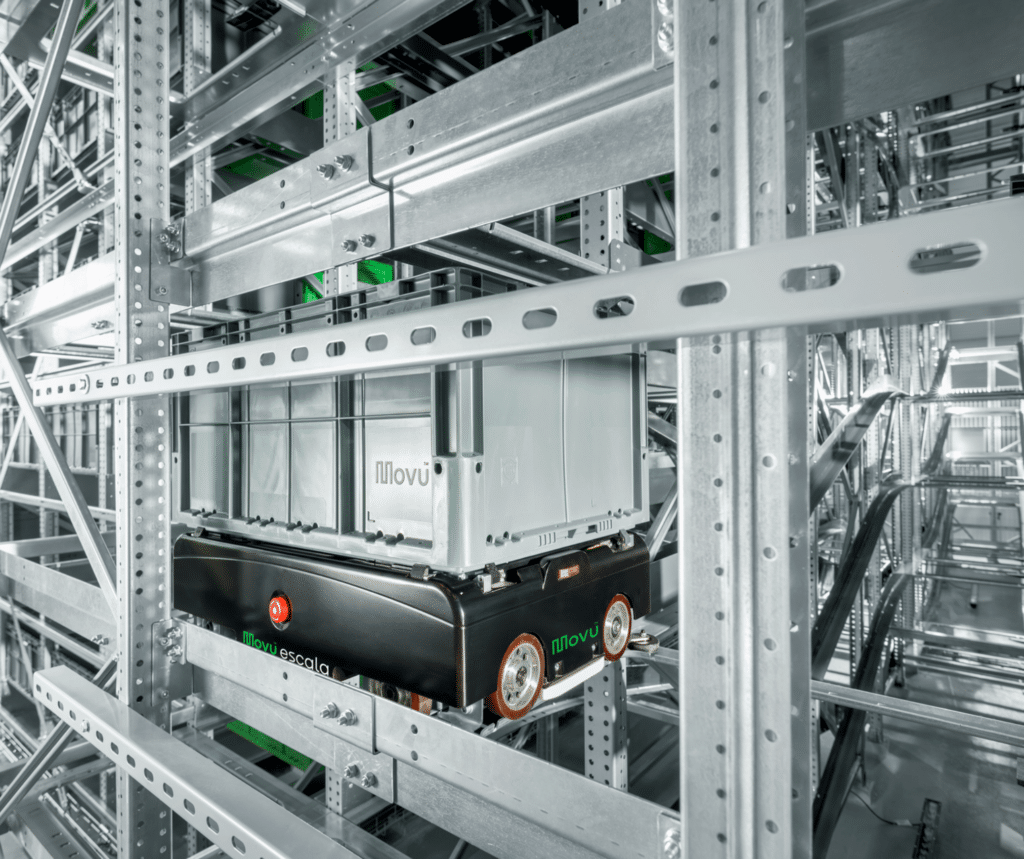

What is a Warehouse Robot?

A warehouse robot is an automated solution designed to simplify and streamline tasks in a warehouse environment. These robots, from picking and packing to sorting and transport, are equipped with the latest technology to ensure fast and precise handling of your goods. Technologies like Pallet Shuttle, Case Shuttle, and Multi-Level Shuttle are just some of the advanced systems used to optimize storage and retrieval processes.

Pallet shuttle

Pallet Shuttle systems are automated solutions designed to transport pallets in and out of their storage locations. They operate in high-density storage systems, where space utilization is crucial, and can significantly improve efficiency by reducing loading time and increasing throughput.

Multi-level shuttle

Multi-Level Shuttles represent the next generation of warehouse automation technology. These robots operate in multi-level storage systems, where they can move vertically and horizontally between different levels. This capability allows for immense space optimization and efficiency, especially in high warehouses. By working on multiple levels simultaneously, Multi-Level Shuttles maximize both storage space and operational speed.

Case Shuttle

Case Shuttles are smaller, more maneuverable robots ideal for handling smaller units such as boxes or trays. These systems are highly efficient in environments with high variation and volume, where quick access to many different products is necessary. Case Shuttles can easily integrate into existing warehouse systems and adapt to changing warehouse needs.

How Warehouse Robots Can Transform Your Business

Warehouse robots are the solution to increasing efficiency and productivity in companies’ warehouse operations. These automated systems reduce manual labor and human errors by constantly performing repetitive tasks with high precision. By working 24/7, warehouse robots maximize warehouse capacity and improve space utilization, leading to significant cost savings and increased workplace safety.

Zolvo has delivered a warehouse robot solution to Alfix A/S, which has experienced significant improvements in their daily operations. See the completed project here and hear Alfix’s CEO, Anders B. Toft, and factory manager, Per B. Jensen, talk about their collaboration with Zolvo:

Case | Alfix A/S

Alfix A/S faced significant challenges with their internal logistics, spending a lot of time on manual pallet handling and experiencing inefficient warehouse management.

Automating the warehouse, including an automated pallet shuttle system, had several benefits for Alfix A/S. They achieved high efficiency and productivity, optimal space utilization, and future-proof handling of the many daily orders.

OUR COMMITMENT TO QUALITY AND SUPPORT

As an independent integrator, we are dedicated to designing and delivering complete turn-key solutions and projects of the highest quality and reliability to our customers. Our team of engineers and technicians ensures that each solution is implemented and maintained to the highest standards, guaranteeing seamless operation and long-lasting performance.

Additionally, we offer comprehensive support and training to ensure you get the most out of your investment. We are always available to answer questions, solve problems, and guarantee a positive experience with our solutions.

Get in touch

Are you ready to take the next step toward implementing warehouse robots? We offer free consultation and assistance to clarify your company’s potential, where we map out the possibilities for automating your processes and internal logistics.

Contact us today for a meeting, so we can help optimize your supply chain through warehouse automation.