Automated Warehouses Are the Core Focus

When competitiveness needs to be improved through warehousing.

Warehouse automation optimizes operations

Technology and automated systems are among the most important tools for optimizing warehouse and logistics operations. They increase productivity, minimize errors, reduce costs, and improve the working environment.

Among the solutions are

- Automated Storage and Retrieval Systems (AS/AR)

- Autonomous Mobile Robots (AMR)

- Conveyor and Sorting Systems

- Automated Picking Systems (Pick-by-Robot)

- Warehouse Management Systems (WMS)

bring pallets to the center when automating the warehouse

Pallets can be stored and retrieved using automated shuttles that run along rails in a racking system. These shuttles transport pallets to and from their storage positions.

This is a highly compact solution, where pallets are placed closely together in deep channels, often across multiple levels. With the pallet shuttle system, high static and dynamic capacity is achieved without manual handling.

The system can operate in environments ranging from refrigerated and frozen storage to standard ambient conditions.

Small units are handled efficiently with multi-level shuttles

With a multi-level shuttle system, goods can be retrieved and stored quickly within a racking system. This is achieved using shuttles that run along rails in the racks and are lifted by an elevator or similar mechanism. The shuttles operate independently and are controlled based on storage locations.

Multi-level shuttles handle small units, such as boxes or trays, making them highly suitable for e-commerce, production, and distribution. This solution is space-saving, flexible, and features automated control.

A customized solution

Zolvo designs the best and most innovative solutions with a focus on your company’s needs. As an independent provider, we can integrate the most suitable products into an optimal overall solution — unrestricted by commitments to a single supplier.

This allows us to optimize the entire value chain, and we look forward to discussing the possibilities with you — not only for immediate implementation but also for scalability once the system is in operation.

With automated shuttles

- Every cubic meter of warehouse space is utilized efficiently—even at height.

- Large volumes of goods can be stored and quickly moved in and out as needed.

- Manual pallet handling is eliminated, reducing the need for labor resources.

- Facilities can be built in both greenfield and brownfield projects.

- The working environment is improved.

- A strong return on investment (ROI) is achieved in the long run.

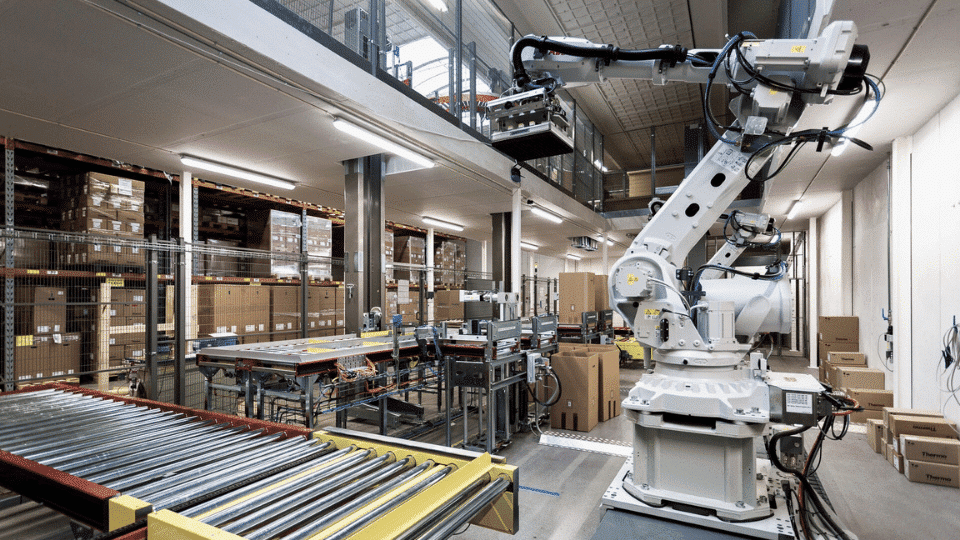

Conveyors and Sorting

Automated warehouses often rely on conveyor systems to move goods efficiently throughout the facility.

Sorting systems also play a crucial role in automated warehouses, ensuring that items are categorized based on destination, order type, or product category. This applies to both inbound and outbound logistics.

Zolvo has extensive experience in implementing solutions that best fit each company’s unique needs.

We have designed solutions for, among others

Picking with Robots

The use of robots for picking goods is rapidly expanding, as they work quickly and accurately and can operate 24/7.

Specifically, robots locate the items and transport them to the packing area. In the packing area, the process is supported by ergonomically designed workstations, vacuum lifts, and other assistive technologies.

The automated warehouse is managed through a WMS.

The WMS system handles the overall coordination of warehouse operations. It connects to a PLC, which controls conveyors and elevators, as well as a traffic control system that manages shuttles. This integrated management ensures highly efficient and secure operations.

Join our journey

We are dedicated to creating value for our customers and partners. Want to learn more about how we can help you? Contact us today at info@zolvo.eu or follow us on LinkedIn.