Kangerlussuaq lufthavn

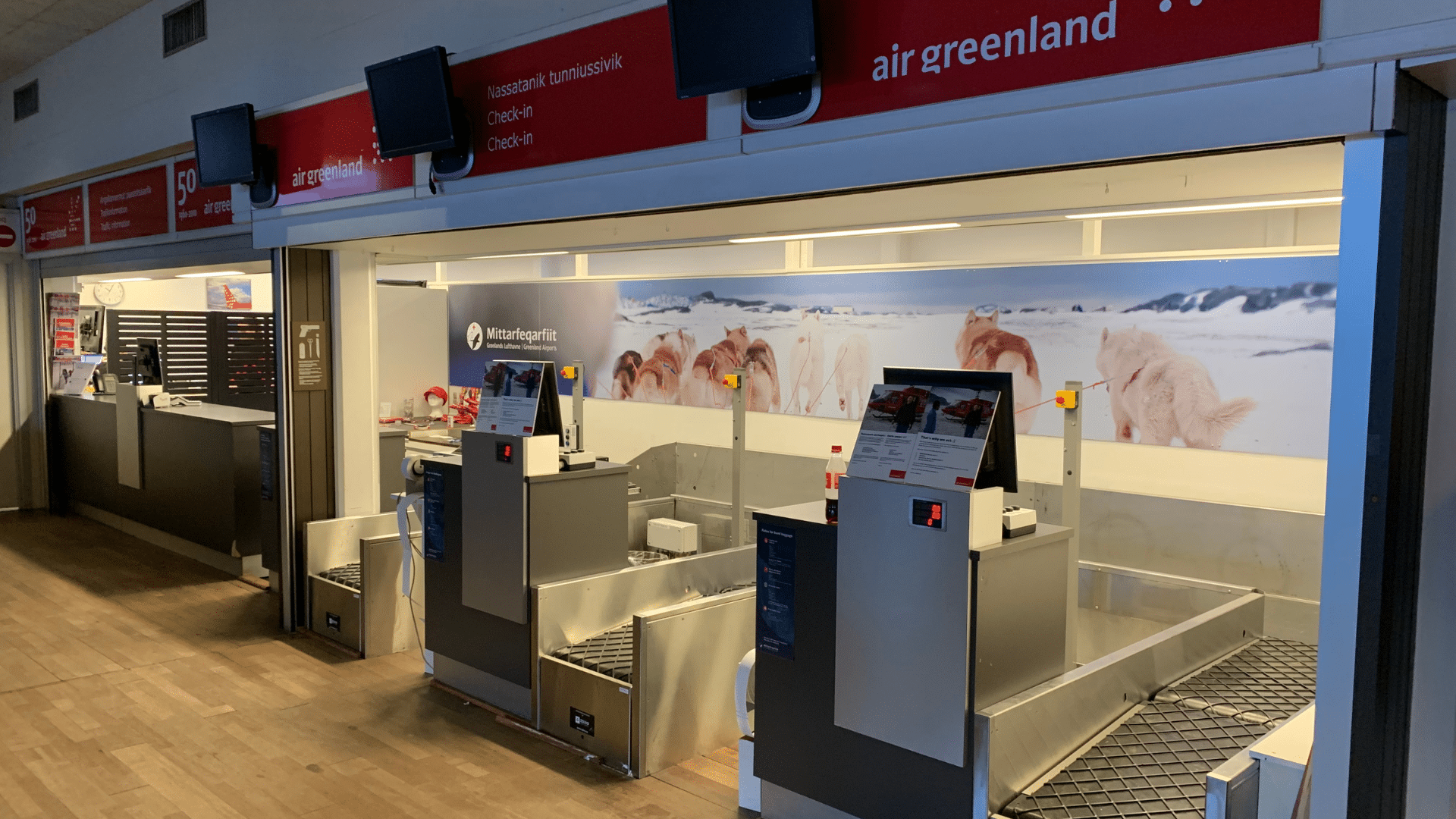

– Opbygning af nyt bagagebåndanlæg

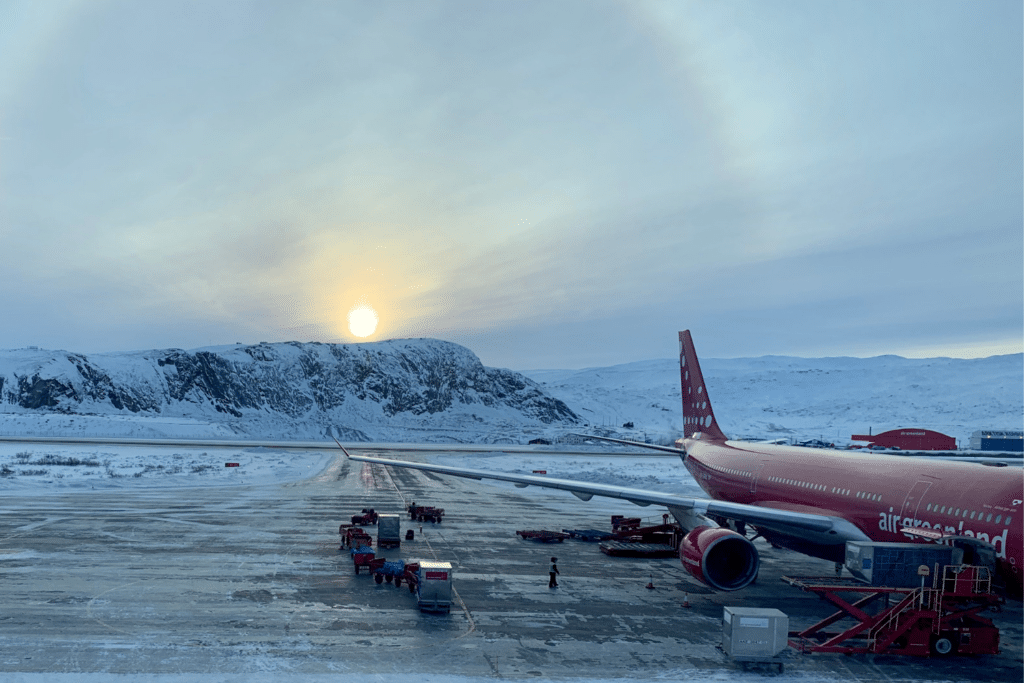

Kangerlussuaq er Grønlands eneste større internationale lufthavn. Det er her, flyene fra den store verden lander og letter og det er også her, de små fly summer som bier, når de transporterer mennesker og gods til og fra byerne.

Lufthavnens bagageområde er knap så stor som andre internationale lufthavne og råder på blot 300m2. Det i sig selv, er en udfordring på regulære standardløsninger og der skulle derfor designes et nyt anlæg, som kunne fungere optimalt på den indsnævrede plads.

Praktisk planlægning

Opgaven bestod i, at det gamle bagageanlæg skulle rives ned og et nyt skulle bygges op på stedet, da der ikke var mulighed for at udvide. Der kræves store planlægnings- og koordineringsprocesser, før den reelle implementering kan påbegynde.

“Efter dialogen med Zolvo, hvor de praktiske ting også kom på plads, gik det faktisk ret stærkt. Zolvo var meget hurtigt på aftrækkeren og de havde styr på det hele.” fortæller Kangerlussuaq Lufthavns sikkerhedschef, Søren Jelager.

Udskiftningen af anlægget har været en nødvendighed. Det gamle bagageanlæg havde 20 år på bagen og bagagebåndet blev ‘spist’ flere steder undervejs og havde oplevet stort slitage. Ydermere kunne der ikke længere fremskaffes reservedele til det gamle anlæg.

Skæve løsninger

Zolvo er specialister i at designe og bygge anlæg, som fungerer optimalt og er tilpasset til den tilgængelige plads.

“Vi kan godt lide ‘de skæve løsninger’ samt design og opbygninger, der ikke findes i forvejen. Her kan vi få alle vores kompetencer i spil og finder altid frem til de mest optimale løsninger for kunden. Anlægget skal ende ud med at være effektiv, driftssikker og velintegreret på den plads, virksomheden har til rådighed. Vi sætter en ære i, at anlægget kan følge fremtidens vækst og efterspørgsel – og dermed også kundens krav.” fortæller Zolvos tekniske direktør, Mads Lissau Jensen.

Tryghed og kreativitet

Når det kommer til at designe og bygge anlæg, er samarbejdet med Zolvo, en oplevelse af tryghed og kreativitet.

“Vi var i et trygt samarbejde. Vi havde nogle idéer, de havde nogle idéer og i fællesskab blev der designet lige netop det bagageanlæg, som passer til vores lufthavn, på de kvadratmeter vi havde til rådighed og de arbejdsprocesser vi har. Det hele har været godt tilrettelagt og blev udført korrekt og effektivt.” fortæller Søren Jalager, og fortsætter.

”Den største udfordring vi mødte, efter at anlægget kom i drift, var de medarbejdere, der før i tiden havde brugt manuelt arbejde i nogle processer, lige skulle vænne sig til at store dele af det nu var automatiseret. Det kan naturligvis sætte anlægget i ‘tvivl’, med de sensorer, der scannede bagagen, at en medarbejder, for eksempel, tog bagagen ud undervejs. Men det er en menneskelig tilvænning og jeg er sikker på, at vi inden længe får den gevinst på ressourcebesparelser, som vi har håbet på.”

Zolvo kan altid se muligheder, der hvor andre ser begrænsninger. Vi har en stor erfaring med logistiske løsninger i eksisterende bygninger, hvor vi sikre kapacitet både for nu og for fremtidige vækst.

“Det er kun fantasien, der sætter grænser for, hvad der er muligt. Vi er dog rigtig gode til at finde optimale løsninger på næsten alle logistiske udfordringer. Vores erfaring med forskellige typer gods og produkter gør, at vi ved, hvad der kræves, for at transportere og pakke dem effektivt.” slutter Zolvos administrerende direktør, Mads Carlsen.

Andre cases

Udforsk vores andre cases og find inspiration til at optimere lager- og logistikprocesser i din virksomhed.